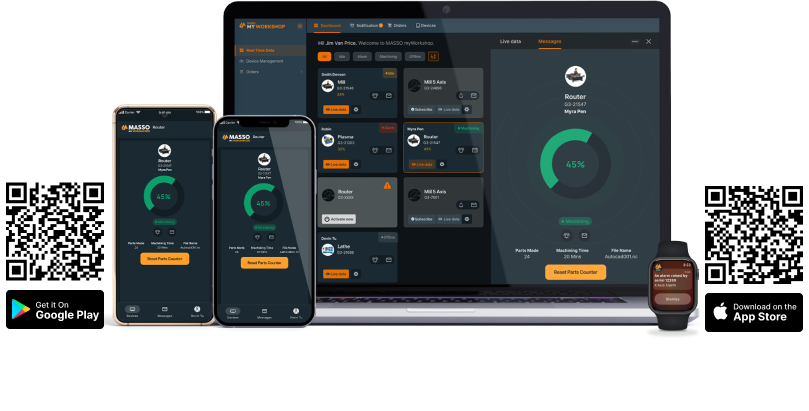

MASSO myWorkshop Phone App – Monitor Your Machines Remotely

Effortlessly oversee your machinery’s performance and status through the MASSO myWorkshop web interface and mobile applications. These tools offer real-time tracking of job progress, alert notifications, and the unique ability to receive tailored remote messages via the MSG command embedded in your G-code files.

Access is straightforward: Log in to your MASSO myWorkshop account, or download the mobile applications using the links provided above.

Why MASSO?

Support at every step

We strive to provide prompt, effective support for all MASSO users. For general CNC machining advice and information, we have a number of online resources. Whether you’re new to CNC programming and machining, new to MASSO, or just looking to get the most out of your MASSO controller, our knowledge base has you covered.

Be part of our development community

Have your say and get early access to MASSO’s next software updates.

Trusted by Machine Manufactures

Bespoke solutions

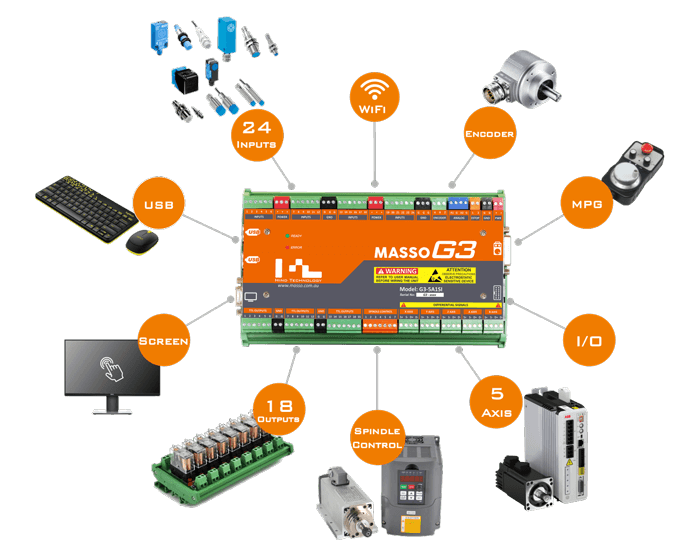

Powered by the latest “PC-less” MASSO G3 controller for fast and reliable machine control.

MASSO controllers offer power, stability and support for machine manufacturers and those looking for bespoke CNC operation solutions. We work with machine manufacturers to develop an integrated CNC solution to meet their needs and specifications, just as we did with CANCAM machines in Canada.

In 2020, after learning of our PC-less CNC controller, CANCAM turned to MASSO for a completely customised controller package for their machines, including specialised sensors and purpose-built software. Today, CANCAM offers each of their CNC machines with MASSO controllers.

Experience the MASSO difference

11,000+ machinists across 60 countries are using MASSO CNC Controllers

Tag or/and mention @massocnc #MakeWithMASSO on your Instagram posts to get featured!