Automatic Tool Length Calibration

On milling machines or router where tools are manually changed and don't use tool holders, calibrating tool length can be a time consuming task. MASSO supports automatic tool length calibration feature called Auto Tool Zero which can be setup to automatically calibrate the length of each tool automatically after tool change.

Once setup, the user simply loads the tool into the spindle and MASSO will move the tool to the predefined tool setter location, calibrate the tool length automatically before going back to the machining position.

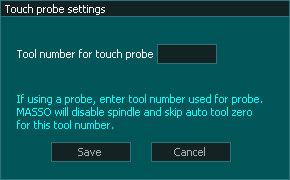

Touch probe to skip

INFORMATION: Touch probe to skip is available on MASSO G3 software version 3.47 and above.

When using a touch probe, if auto tool zero is enabled, the controller will try to automatically do an auto tool zero which can damage the touch probe. If a tool number is entered in the above settings then MASSO will automatically skip auto tool zero for this tool number and the user can enter the calibrated length of the touch probe in the F4-Tools & Work Offset screen.

This also disables the spindle so that it cannot be accidentally turned on when the touch probe is loaded.

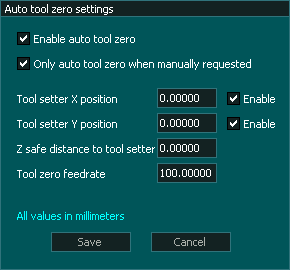

Only auto tool zero when manually requested

INFORMATION: Only auto tool zero when manually requested is available on MASSO G3 software version 3.47 and above.

On machines where pre-calibrated tool holders are used for changing tools, auto tool zero is not required on each tool change and only required when calibrating the tool into the tool holder.

If the above option is enabled then MASSO will not do an auto tool zero on tool change but the user can manually run the auto tool zero cycle by pressing the "Auto Tool Zero" button in the F4-Tools & Work Offset screen under the edit tool options. After pressing the "Auto Tool Zero" button, the system will run the auto tool cycle and the length of the tool is automatically saved into the memory.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese