Plasma POST Processor Requirements

MASSO version5 and DTHC Plasma Post Processor Requirements

This document outlines the new requirements for a post processor to be used with Version 5 software and MASSO Plasma DTHC unit.

It is an aid to those who wish to design their own post processors.

This post processor will work for both THC and DTHC users but will not work with Version 4 plasma and below

A sample Gcode file has been added to the end of this document along with screenshots to illustrate and comments to the Gcode.

Overview

MASSO has designed an integrated THC unit for use with the MASSO CNC controller.

This requires a new Post processor as much of the normal functions carried out through Gcode is now built into MASSO simplifying the Gcode required.

To achieve this a new Gcode has been created G200

This would be placed at the start of the Gcode file and defines the various parameters that will determine how MASSO will work. This Gcode is only required once unless the cutting parameters need to change during the cut.

While G200 can be placed at the start of the file it is not mandatory for it to be in the first line.

· The G200 must appear before the first M3 command in the Gcode file

· A new G200 may be issues if cutting parameters need to change during the cut.

· While in Plasma mode the tool number must remain Tool 112.

G200 Syntax & Parameters

- G200 uses the values to populate the Plasma parameters tab

- F Value – Touch off feed rate

- P Value – Piercing Height

- D Value – Piercing delay This value is defined in Milliseconds

- C Value –Cutting height

- V Value - Cutting voltage

, if set to “0” then the system goes into the “Auto Voltage” option where the system samples the voltage at cutting height and then maintains this voltage for the entire cut. To make use of this parameter the MASSO DTHC module is required.

, if set to “0” then the system goes into the “Auto Voltage” option where the system samples the voltage at cutting height and then maintains this voltage for the entire cut. To make use of this parameter the MASSO DTHC module is required. - A Value - Feed rate Anti Dive

, (Please note that this parameter has not yet been implemented but will be added at a future date) This value is a percentage of the X & Y axis feed rate below which the Z-axis will lock when under THC control to prevent the torch from moving into the material. The axis will unlock and the THC resume operation once the feed rate increases above this value.

, (Please note that this parameter has not yet been implemented but will be added at a future date) This value is a percentage of the X & Y axis feed rate below which the Z-axis will lock when under THC control to prevent the torch from moving into the material. The axis will unlock and the THC resume operation once the feed rate increases above this value. - O Value - Ohmic ON/OFF. 0 is Ohmic OFF, 1 is Ohmic ON.

- S Value - Stop after piercing and wait for Cycle start. 0 is do not stop, 1 is Stop and wait for Cycle Start.

Example program

N10 G200 F150 P5.5 D500 C3.1 V116 A90 O1 S0

M667 – Plasma – Turn THC Function On

This command is used to switch On the THC automatic Z axis control function in the plasma version.

Syntax & Parameters

· M667

· F Value - this is the feed rate of the Z axis that the will be used to move torch up/down when in THC mode. If no feed rate is specified MASSO will use the maximum feed rate of the Z axis as the THC feed rate. Once a THC feed rate has been specified it will be remember until overwritten by a new F value allowing subsequent M667 commands without an F value to be used.

Example program

N10 M667 F500

The above program switches On the THC function and sets Z axis feed rate during THC control to 500.

M666 – Plasma – Turn THC Function Off

This command is used to switched OFF the THC automatic Z axis control function in the plasma version.

Syntax & Parameters

· M666

Example program

N10 M666

The above program switches Off the THC function.

Tool Change Command

- T112 M06 must appear in the Gcode file before cutting starts to put MASSO into Plasma mode. Ideally in the header of the Gcode file.

- Changing to a different tool number will cancel Plasma mode.

Example program

N10 T112 M06

· The above program Changes MASSO into Plasma mode.

G200

A G200 with no parameters after it will turn off the G200 operation and the plasma will work in a legacy mode where all operations need to be done manually using Gcode.

The default setting for G200 when MASSO is powered on is G200 is turned on so if running old files a G200 command should be added to the start of the file to switch MASSO to legacy mode.

This can also be done by issuing a G200 in MDI but adding it to the file better.

Once G200 is turned off it will remain off until turned on again or MASSO is repowered.

G200 can be used with an external THC unit such as a Proma 150 and is mandatory when using the MASSO DTHC unit.

When G200 is active many of the standard plasma operations are automated which greatly simplifies the Gcode required.

When an M3 is issued the following start sequence will happen automatically.

- Probing will start automatically using the F parameter as the probing feed rate. once the touch off been triggered the torch height will be set.

- The torch will automatically move to piercing height defined in parameter P

- The torch will start the arc

- On receipt of the Arc ok signal the piercing Delay timer defined in parameter D will start.

- At the end of the delay time the Torch will automatically move to the cutting height defined in parameter C

INFORMATION: It is recommended that GCode use the G200 features whether you are using a DTHC or an older Legacy THC unit.

F - Touch off feed

This is the Touch off feed rate used in the automatic probing as part of G200 when it is active

P - Piercing height

This defines the Piercing Height used as part of G200 when it is active.

It is the height the torch will move to perform the piercing.

D - Piercing delay

This is the piercing delay used as part of G200 when it is active.

This is the time the torch will wait for the material to be pierced before continuing to cutting height.

This value is defined in mS eg a value of 2000 is 2 Seconds

C - Cutting height

This is the cutting height used as part of G200 when it is active.

This is the height the torch will automatically move after the piercing is complete.

V - Cutting voltage

This defines the cutting voltage that the MASSO DTHC uses to set the torch height when cutting.

If a voltage is defined it will maintain this voltage while cutting.

The voltage can be altered in real-time by using the Torch UP and Torch Down buttons on the F2 screen

Each press will change the voltage by 1 volt.

A new value can be typed into the cutting Voltage box on the Plasma tab on the F2 screen

If the C Value is set to 0 in G200 MASSO will use the “Auto Voltage” option where the system samples the voltage at cutting height each time the plasma starts and then maintains this voltage for the rest of that cut.

A - Anti-dive

Please note that this parameter has not yet been implemented but will be added at a future date)

This defines the feed rate anti-dive percentage value. It is used to lock the Z-axis when the axis slows down to prevent the torch from dropping into the material. This normally occurs when cutting arcs.

This value is a percentage of the X & Y axis feed rate below which the Z-axis will lock when under THC control to prevent the torch from moving into the material. The axis will unlock and the THC resume operation once the feed rate increases above this value.

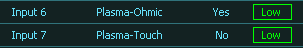

O - Ohmic

This is the Ohmic touch off parameter.

MASSO has 2 touch off inputs that can be used for Plasma touch off. Plasma Touch and Plasma Ohmic

When O0 is set the Plasma-Touch is used. This is usually a switch built into the torch that activates then the torch is pressed into the material surface.

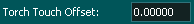

Then this input is used the Torch Touch Offset is used to calculate the torch height.

When O1 is set the Plasma-Ohmic is used. This type of touch off uses the electrical connection between the torch tip and the material itself to detect the torch height.

The Ohmic touch does not use an offset value.

You can configure both touch types on your machine and select the one best suited at the time.

Only one can be active at a time.

You can manually switch between them by using the Ohmic Button

Ohmic is active when it is Yellow

S - Stop

When piercing thicker material the molten metal is moved to the surface of the material until such time as the material is pieced.

This can cause a build up on the surface of the material that the torch can run into.

Use of the S parameter in the G200 can be used when cutting material that presents this problem.

When S1 is set, and an M3 command is issued the torch will touch off the material, move to the piercing height and after the piercing delay has finished the Plasma will turn off and the torch ascend to the Z home position.

The material surface can now be cleaned and when ready the Cycle Start button is pressed.

The torch will now rapid down to the cutting height, the Plasma will start and the cut will commence.

This sequence will occur on each M3 command.

If S0 is set there will be no stop between piercing and moving to cutting height.

Default is S0 when MASSO is powered on

The last S value will be remembered until it is changed or MASSO is repowered.

Build up left after piercing thick material

To automate S0 or S1 within the post processor one method is to compare the material thickness defined in the job parameter with a reference thickness stored within the post processor or within the Cam software. If the material thickness is equal to or exceeds the reference thickness then S1 is set otherwise S0 is set.

Another method is an option within the job set up is a switch to turn S on or off as needed. This relies on the user remembering to manually select the option during setup but affords more flexibility.

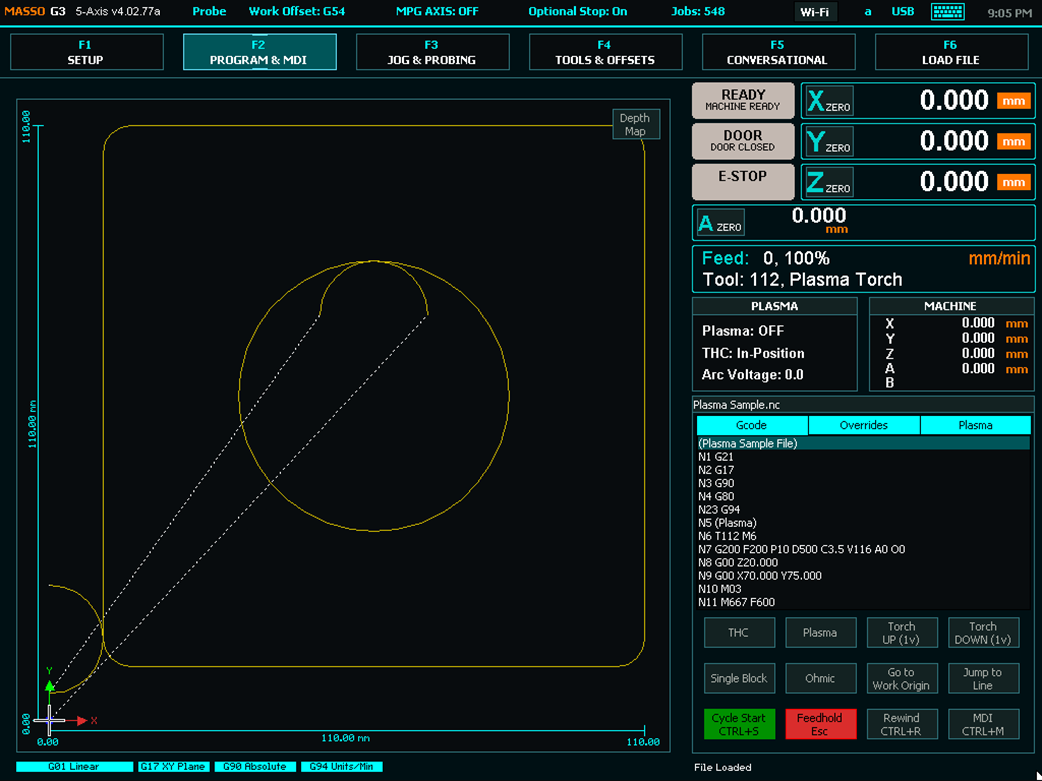

Sample Gcode file

The following is a Sample Gcode file which includes the G200, M667 and M666 Gcode commands.

Note that there is no requirement for Probing Gcode routines in this file.

The M03 will automatically perform the Probing of the material surface, the Piercing delay and setting the cutter to the cutting height using information contained in the G200 Gcode command.

Because MASSO manages all Z axis moves while cutting there only needs to moves to the Safe Z height between cuts.

Comments added in red

(Plasma Sample File)

N1 G21

N2 G17

N3 G90

N4 G80

N23 G94

N5 (Plasma)

N6 T112 M6 (This is required to put MASSO into Plasma Mode. The Tool number must always be Tool 112)

N7 G200 F200 P10 D500 C3.5 V116 A0 O0 S0 (This Gcode sets the Plasma Parameters)

N8 G00 Z20.000 (Safe Z move)

N9 G00 X70.000 Y75.000

N10 M03 (Turn Plasma on, Probe, Delay, Set cutting height)

N11 M667 F600 (This will Turn the THC on at a Z axis feed rate of 600mm/min)

N12 G03 X60.000 Y85.000 I-10.000 J0.000 F3000

N13 G03 X35.000 Y60.000 I0.000 J-25.000

N14 G03 X60.000 Y35.000 I25.000 J0.000

N15 G03 X85.000 Y60.000 I0.000 J25.000

N16 G03 X60.000 Y85.000 I-25.000 J0.000

N17 G03 X50.000 Y75.000 I0.000 J-10.000

N18 M666 (This Turns the THC off)

N19 M05 (Turns Plasma Off)

N20 G00 Z20.000 (Safe Z move)

N21 G00 X0.000 Y5.000

N22 M03

N23 M667 F600

N24 G03 X10.000 Y15.000 I0.000 J10.000 F3000

N25 G01 X10.000 Y105.000

N26 G02 X15.000 Y110.000 I5.000 J0.000

N27 G01 X105.000 Y110.000

N28 G02 X110.000 Y105.000 I0.000 J-5.000

N29 G01 X110.000 Y15.000

N30 G02 X105.000 Y10.000 I-5.000 J0.000

N31 G01 X15.000 Y10.000

N32 G02 X10.000 Y15.000 I0.000 J5.000

N33 G03 X0.000 Y25.000 I-10.000 J0.000

N34 M666

N35 M05

N36 G00 Z20.000 (Safe Z move)

N37 M30

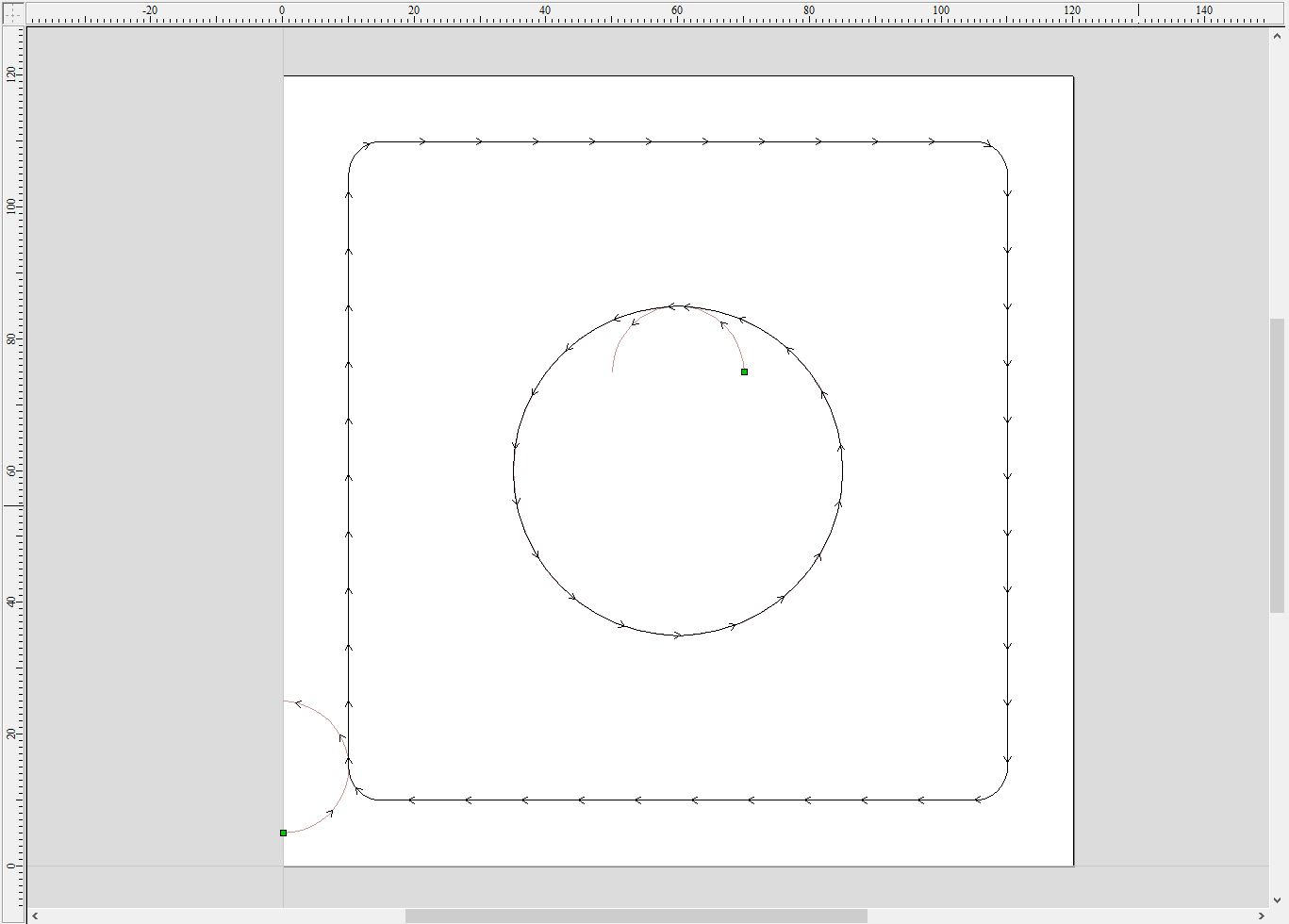

CAD/CAM Toolpath of Sample File with lead in and lead out

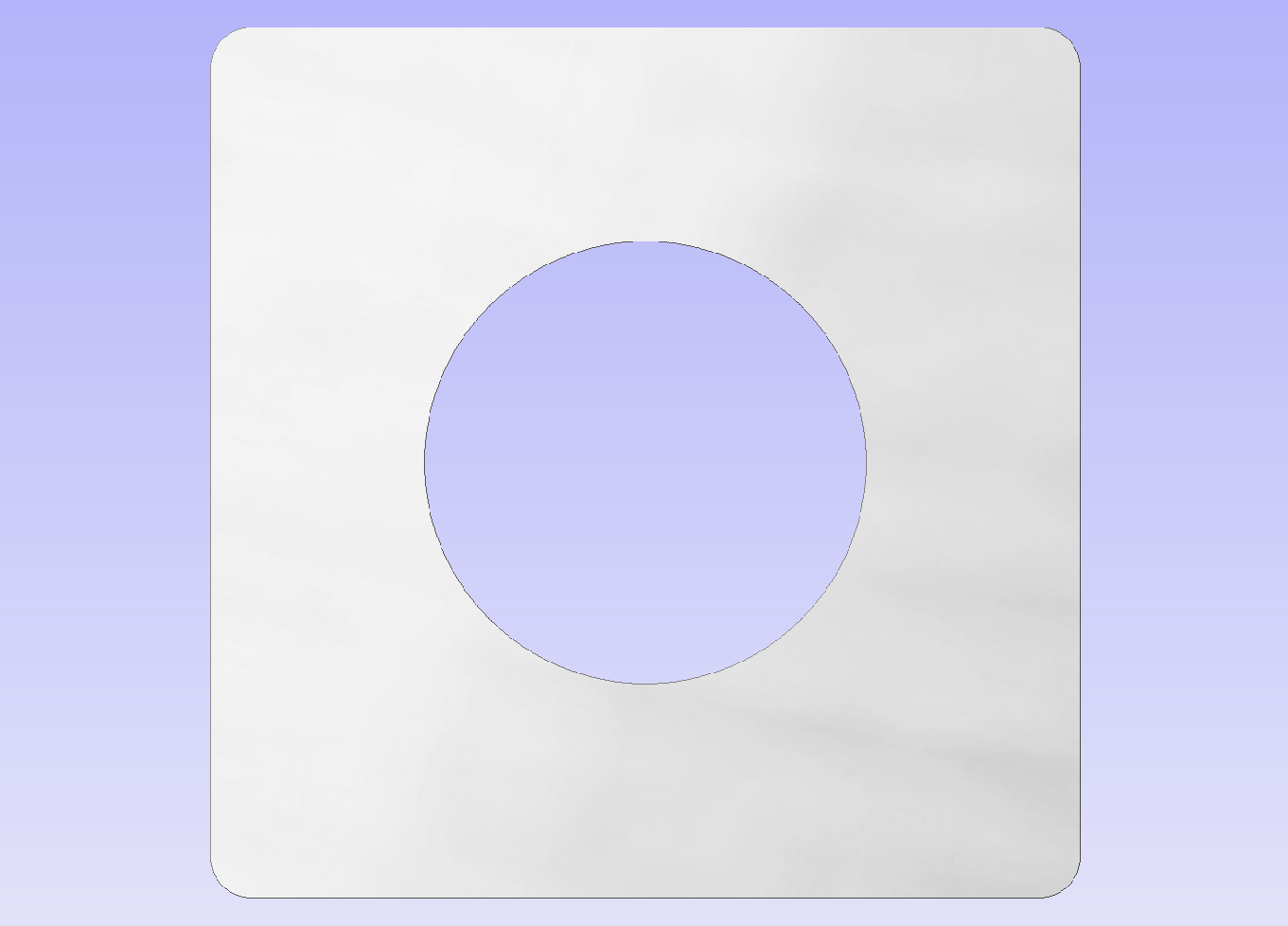

Completed cut of Sample File

Gcode file as seen on MASSO Screen

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese